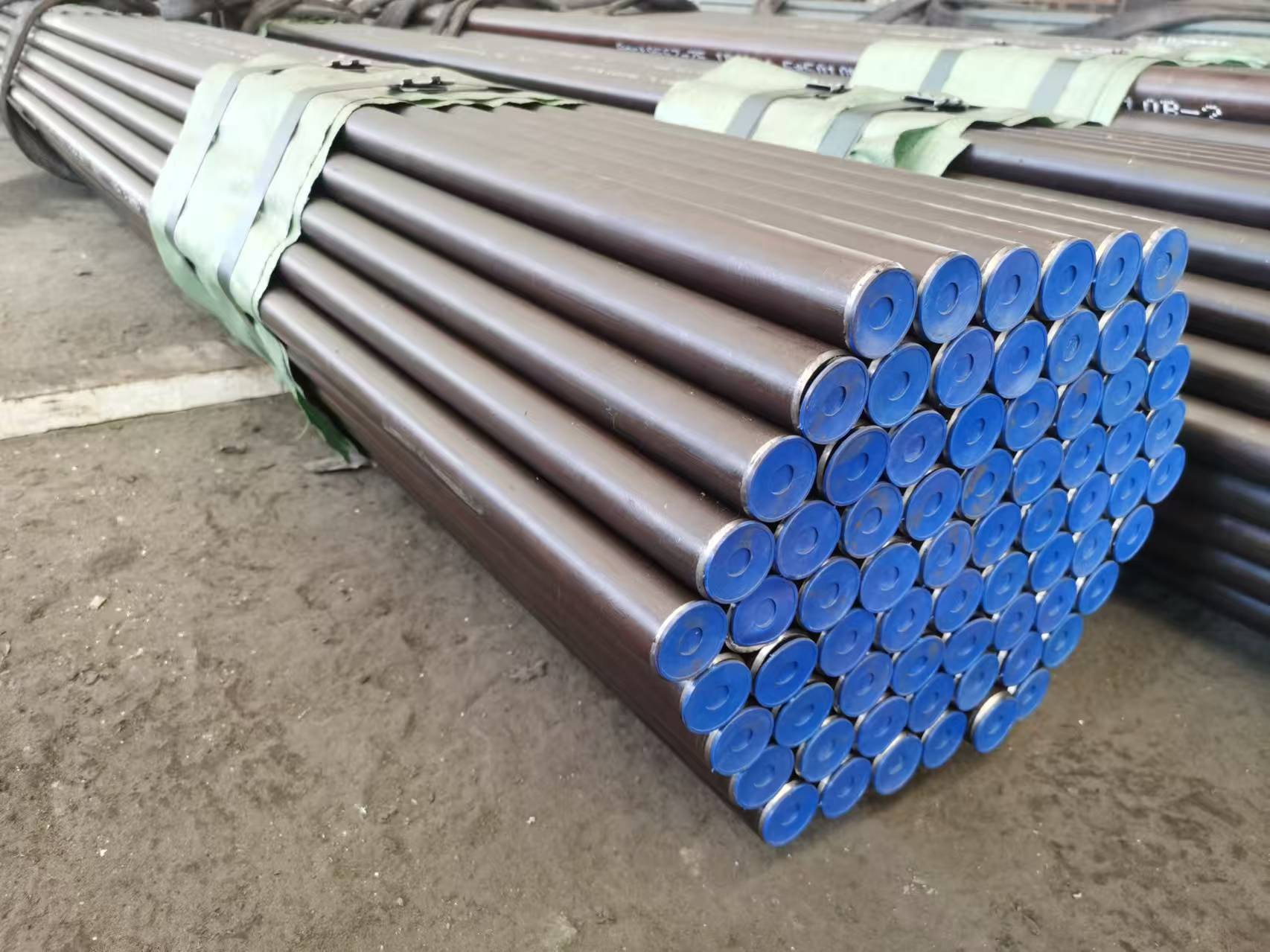

ASME SA192 Seamless Carbon Steel Boiler Tubes – Premium Quality for Industrial Steam Systems These high-performance seamless carbon steel boiler tubes are engineered to meet the rigorous specifications of ASME standards, ensuring exceptional safety, reliability, and efficiency in demanding thermal environments. Designed specifically for use in power generation and industrial heating applications, they serve as a cornerstone component in boiler systems where consistent performance under extreme pressure and temperature is non-negotiable. Key Features: - Manufactured from premium-grade carbon steel with optimized mechanical properties - Seamless construction eliminates weld seams, reducing risk of leakage and structural failure - Enhanced resistance to corrosion, erosion, and thermal stress over extended service life - Consistent dimensional accuracy and surface finish for reliable installation and operation - Compliant with international material standards including ASTM A192 and ASME BPVC Section I Detailed Description: ASME SA192 seamless boiler tubes are produced using advanced manufacturing techniques that guarantee uniformity across every batch. Unlike welded alternatives, these pipes offer superior integrity due to their single-piece structure, which minimizes weak points and enhances long-term durability. The carbon content and heat treatment processes are carefully controlled to ensure adequate tensile strength, ductility, and creep resistance—critical factors when operating at elevated temperatures (up to 750°F or 400°C) and pressures exceeding 1,000 psi. These tubes facilitate efficient heat transfer between combustion gases and water/steam, optimizing energy utilization in both utility-scale and process boilers. Their compatibility with various feedwater treatments and minimal maintenance requirements make them ideal for continuous-duty operations in refineries, chemical plants, and district heating facilities. Applications: Ideal for use in steam boilers, superheaters, economizers, and reheaters within fossil fuel and biomass-fired power stations. Also widely adopted in petrochemical processing units, paper mills, and food industries requiring clean, stable steam supply. Suitable for both new installations and retrofit projects seeking improved system longevity and operational safety. User Feedback: Operators and engineers consistently report reduced downtime and enhanced boiler efficiency after switching to ASME SA192 tubes. One plant manager noted, “The seamless design has eliminated recurring leak issues we experienced with previous tube materials.” Another user praised the consistent performance across multiple seasons, stating, “Even after years of exposure to aggressive condensate chemistry, our tubes show no signs of premature degradation.” Frequently Asked Questions: What makes ASME SA192 different from other boiler tubing materials? It offers a proven combination of strength, uniformity, and compliance with internationally recognized codes, making it suitable for critical pressure vessel applications where failure is not an option. Are these tubes suitable for low-temperature environments? While primarily designed for high-temperature service, they maintain good toughness down to -20°C, though specific cold-end applications should be evaluated based on local code requirements. How do I verify authenticity and quality during procurement? Look for mill test reports confirming chemical composition, mechanical testing results, and adherence to ASME Section II Part A and B specifications. Why choose seamless over welded boiler tubes? Seamless tubes eliminate potential failure points associated with welding, provide better fatigue resistance, and offer more predictable behavior under cyclic thermal loading. BAODELY HUAIAN METAL TECHNOLOGY CO., LTD specializes in precision seamless steel pipe solutions tailored for global clients. With decades of experience in producing carbon steel, low-temperature alloy, and boiler-grade tubes, the company delivers unmatched value through strict quality control, competitive pricing, and consistent product excellence. Whether you're upgrading existing infrastructure or designing a new boiler system, ASME SA192 seamless carbon steel tubes represent a trusted investment in performance, safety, and operational continuity.

Product Categories : Boiler Pipe > ASME SA192 Boiler Pipe