High-Quality

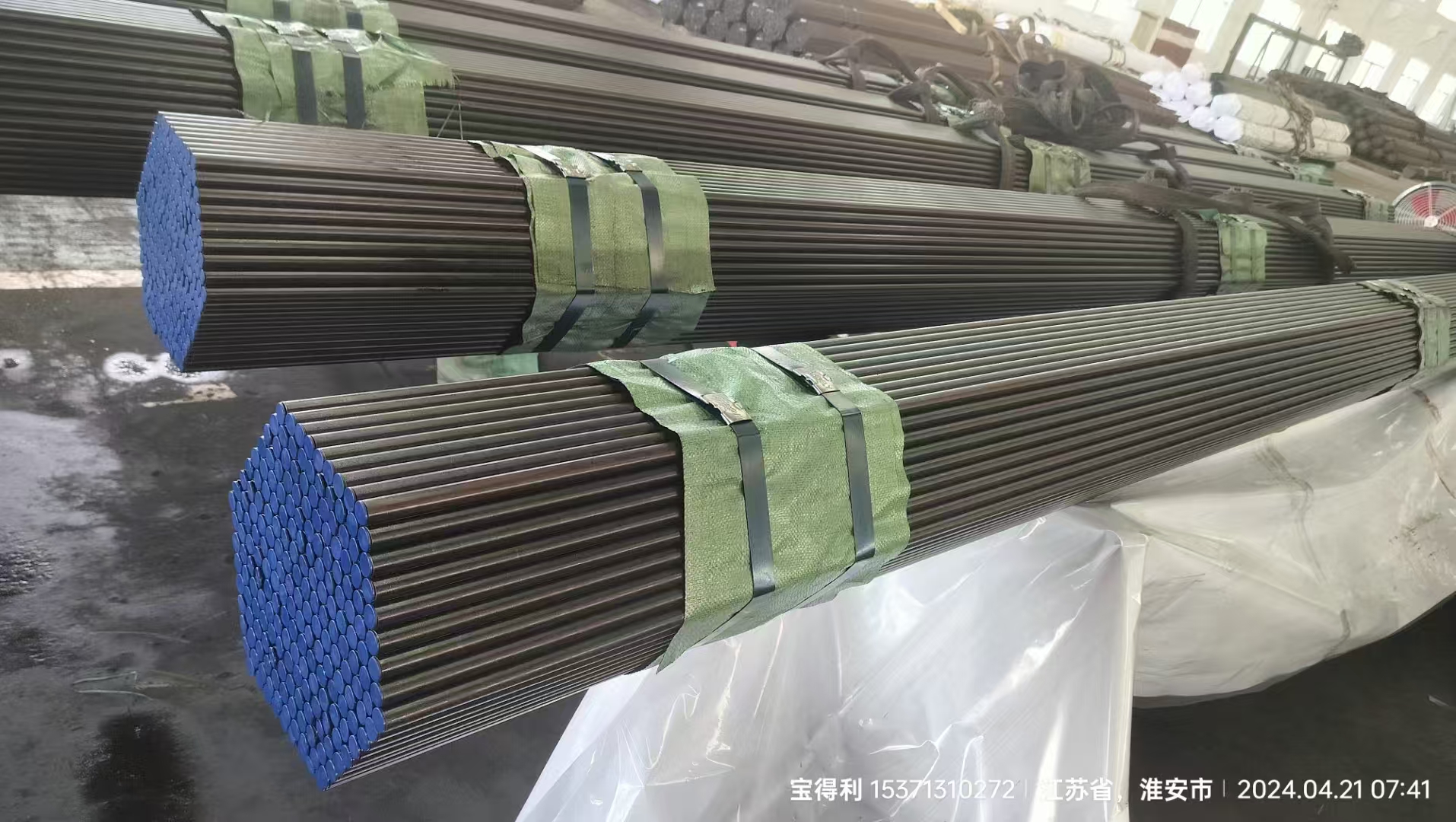

ASME SA213 Boiler Pipe for Industrial Applications – Superior Performance in Extreme Conditions This premium-grade seamless steel pipe, manufactured under the stringent standards of ASME SA213, delivers exceptional reliability and durability for high-pressure and high-temperature environments. Designed for critical applications in power generation, petrochemical processing, and industrial boiler systems, this alloy steel tubing ensures safe, efficient operation even under the most demanding conditions. Key Features: Engineered with precision from selected raw materials and advanced manufacturing techniques, each pipe undergoes meticulous chemical composition control—ensuring optimal levels of chromium, molybdenum, and other alloying elements. This results in outstanding resistance to thermal oxidation, corrosion, and mechanical fatigue. With precise dimensional accuracy, uniform wall thickness, and a smooth, defect-free surface finish, it minimizes flow resistance and enhances heat transfer efficiency. Mechanical properties include high tensile strength, excellent toughness, and resilience against sudden temperature shifts and pressure variations. Detailed Description: Manufactured using state-of-the-art processes including ultrasonic testing, hydrostatic pressure testing, and mechanical property verification, every unit meets or exceeds international quality benchmarks. The seamless construction eliminates weld seams that could lead to stress concentration or failure points, making it ideal for continuous operation in harsh environments. Its microstructure is carefully controlled to maintain stability across a wide range of temperatures—from sub-zero cold-start conditions to sustained exposure above 600°C—making it a preferred choice for superheater tubes, reheater lines, and main steam piping in modern power plants. Applications: Ideal for use in utility boilers, fossil fuel power stations, nuclear facilities, and chemical processing units where material integrity directly impacts system safety and operational uptime. Suitable for both new installations and retrofit projects requiring robust, long-lasting components that comply with ASME BPVC Section I and II standards. Also widely adopted in oil refineries, desalination plants, and heavy-duty industrial heating systems where consistent performance under extreme conditions is non-negotiable. Customer Feedback: Users consistently report improved energy efficiency, reduced maintenance intervals, and fewer unplanned shutdowns when switching to this grade of boiler tube. Engineers appreciate its predictable behavior during thermal cycling and its compatibility with existing system designs. Many cite the manufacturer’s commitment to quality assurance as a key factor in their decision to standardize on these pipes across multiple sites. Frequently Asked Questions: What makes ASME SA213

Boiler Pipe different from carbon steel alternatives? It offers superior creep strength and oxidation resistance at elevated temperatures due to its alloyed composition, which carbon steel lacks. Is this pipe suitable for ultra-supercritical power plants? Yes—it meets the requirements for temperatures up to 650°C and pressures exceeding 25 MPa, making it appropriate for advanced coal-fired and biomass-based power generation systems. How does the seamless design improve reliability? By eliminating weld joints, the seamless structure reduces potential failure points, enhancing structural integrity over time, especially under cyclic loading. Can it be used in corrosive environments like those found in chemical industries? Absolutely—the alloy formulation provides excellent resistance to sulfuric acid, chlorides, and other aggressive media commonly encountered in refining and chemical processing operations.

Product Categories : Boiler Pipe > ASME SA213 Boiler Pipe