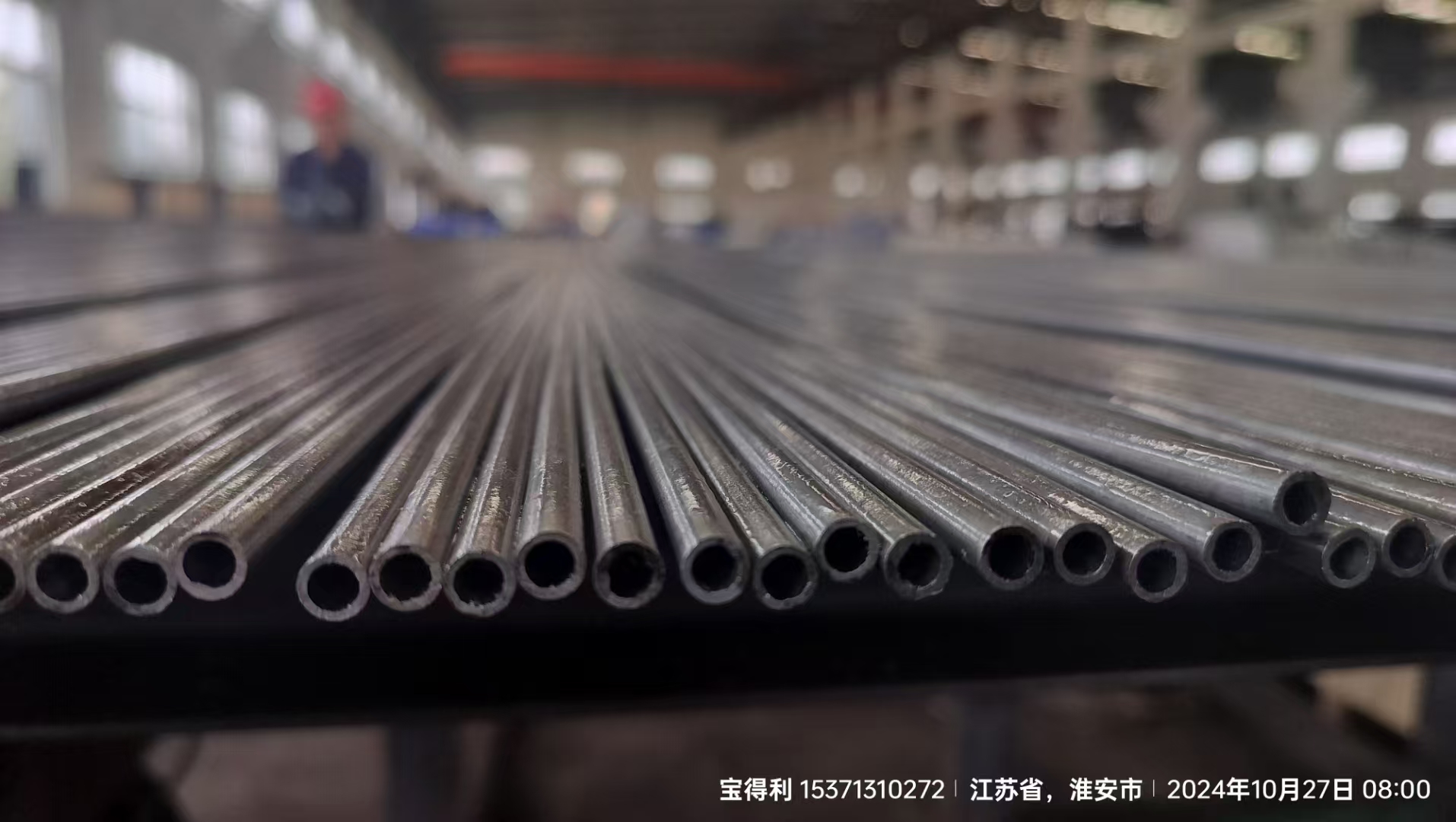

ASTM A334 Grade 6 Seamless Cryogenic Pipe – Engineered for Extreme Cold, Built for Safety and Reliability This high-performance low-temperature

Carbon Steel Pipe is meticulously manufactured to meet the rigorous demands of cryogenic applications across global industries. Designed specifically for environments as cold as -45°C and beyond, ASTM A334 Grade 6 seamless pipe offers exceptional toughness, structural integrity, and leak-free operation under extreme thermal stress. It stands as a benchmark in cryogenic piping systems, providing a cost-effective yet highly dependable solution where material failure could lead to catastrophic consequences. Key Features - Superior Low-Temperature Toughness: Achieves impact energy ≥18 joules at -45°C, minimizing embrittlement risks - Optimized Chemical Composition: Carbon ≤0.30%, manganese 0.29–1.06%, phosphorus and sulfur ≤0.025% for enhanced ductility and strength - Seamless Construction: Eliminates weld-related weaknesses, ensuring uniformity and pressure resistance - Mechanical Strength: Tensile strength ≥415 MPa, yield strength ≥240 MPa for reliable performance under cryogenic loads - Dimensional Stability: Maintains consistent shape and sealing capability despite rapid temperature fluctuations Detailed Description Manufactured in strict compliance with ASTM A334 standards, this cryogenic pipe is produced from premium low-carbon steel billets using advanced seamless rolling techniques. Unlike traditional carbon steel pipes that degrade in sub-zero conditions, ASTM A334 Grade 6 has been engineered through precise alloying and processing to deliver unmatched resilience at temperatures as low as -162°C—commonly encountered in liquid nitrogen or liquefied natural gas (LNG) handling. The controlled levels of silicon (≥0.10%) improve oxidation resistance, while manganese enhances fracture toughness, making it ideal for long-term service in cryogenic storage tanks, transport vessels, and refrigeration infrastructure. Each pipe undergoes comprehensive non-destructive testing, hydrostatic pressure checks, and low-temperature Charpy V-notch impact tests to guarantee zero defects and maximum safety. Applications Ideal for use in LNG terminals, cryogenic chemical processing units, industrial gas storage facilities, and ultra-low-temperature pipelines in pharmaceuticals, aerospace, and food freezing sectors. Whether transporting liquefied gases, supporting cryogenic reactors, or forming part of critical containment systems, this pipe ensures operational continuity without compromising on safety margins. Its compatibility with both welded and flanged connections makes it adaptable to various system designs, while its smooth internal surface reduces flow resistance and energy loss—a crucial factor in efficient cryogenic fluid transfer. Customer Feedback Users worldwide praise its reliability in harsh cold environments, noting how it outperforms standard carbon steel pipes in preventing brittle fractures during sudden temperature shifts. Many project engineers highlight its value in reducing maintenance costs and enhancing system uptime, especially when compared to more expensive nickel-based alloys. Customers often remark on the consistent quality batch after batch, which contributes significantly to risk mitigation in sensitive industrial operations. Frequently Asked Questions What makes ASTM A334 Grade 6 different from regular carbon steel pipes? It features optimized chemistry and manufacturing processes tailored for cryogenic conditions, offering superior impact resistance and ductility below freezing points. Is it suitable for transporting liquefied natural gas (LNG)? Yes, it's widely used in LNG infrastructure due to its ability to withstand temperatures down to -162°C without embrittlement. How does it compare to alloy steel pipes in low-temperature applications? While some alloy steels offer better performance at extremely low temperatures, ASTM A334 Grade 6 provides an excellent balance of cost, availability, and functionality for most cryogenic projects. Does it require special installation practices? Standard welding and joining methods apply, but all connections must be tested under simulated cryogenic conditions to ensure tightness and structural soundness.

Product Categories : Low Temperature Steel Pipe > ASTM A334 Pipe