Baodely Huaian Metal Technology Co., Ltd.

High Temperature Steel Pipe,High Temperature Steel Tube,ASTM A335 Steel Pipe

Baodely Huaian Metal Technology Co., Ltd.

High Temperature Steel Pipe,High Temperature Steel Tube,ASTM A335 Steel Pipe

Model No.: ASTM A335

Brand: BAODELY

Standard: Astm

Section Shape: Round

Place Of Origin: China

Application: Fluid Pipe, Boiler Pipe, Hydraulic Pipe, Gas Pipe, Chemical Fertilizer Pipe, Structure Pipe

Production Process: Cold Drawn

Tolerance: ±10%

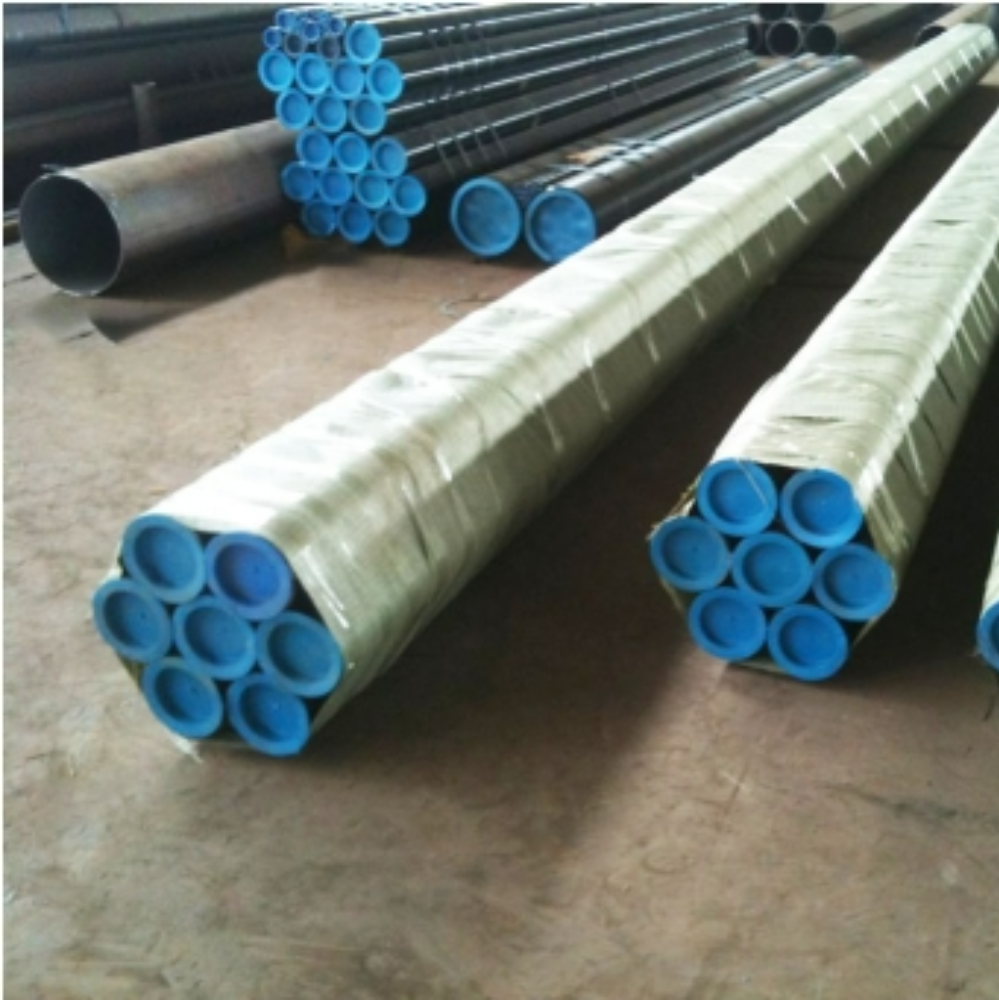

Category: Seamless Steel Pipe

Processing Service: Bending, Decoiling, Cutting

Transportation: Ocean,Land

Place of Origin: CHINA

Certificate: ISO9001

Port: SHANGHAI,QINGDAO,LIANYUNGANG

Astm A335 High-Temperature Alloy Steel Pipe – Superior Performance for Extreme Industrial Conditions

Engineered for reliability in the most demanding thermal environments, ASTM A335 high-temperature steel pipe is a premium-grade alloy solution designed to maintain structural integrity and operational efficiency at sustained temperatures up to 550°C or beyond. This seamless or welded piping system is manufactured using advanced metallurgical techniques and carefully balanced alloy compositions featuring chromium, molybdenum, and tungsten—elements that synergistically enhance creep resistance, oxidation stability, and mechanical strength under prolonged heat exposure.

The precise formulation of this alloy ensures exceptional durability in applications where conventional carbon steel would fail due to softening, scaling, or embrittlement. With its optimized microstructure and uniform wall thickness achieved through precision manufacturing processes, ASTM A335 Pipe minimizes stress concentrations and maximizes pressure-handling capability in high-temperature, high-pressure systems. Its smooth internal surface further reduces frictional losses, improving flow dynamics for steam, hydrocarbons, and other hot process media commonly found in industrial power generation and chemical processing units.

Manufactured to meet stringent international standards, each batch undergoes comprehensive quality assurance protocols including high-temperature tensile testing, Charpy impact evaluation, metallographic examination, and non-destructive testing (NDT). These rigorous checks confirm compliance with ASTM A335 specifications and ensure consistent performance across diverse operating conditions—from boiler feedwater lines in fossil fuel plants to reformer tubes in petrochemical refineries.

Ideal for use in thermal power stations, oil refineries, chemical processing facilities, and gas treatment plants, ASTM A335 piping offers long-term corrosion resistance, reduced maintenance requirements, and enhanced safety margins in critical infrastructure. Whether supporting superheated steam transfer, catalytic cracking operations, or high-temperature fluid transport, this alloy steel pipe delivers dependable service life and operational continuity in harsh environments.

Customers worldwide praise the balance of performance, cost-effectiveness, and consistency offered by Baodely Huaian Metal Technology Co., Ltd.—a trusted manufacturer specializing in precision seamless steel pipes. Their product range includes Carbon Steel Pipe, low-temperature steel pipe, boiler tube, alloy steel pipe, and Precision Steel Pipe, all produced with strict adherence to global quality benchmarks. The company’s commitment to innovation, material science, and sustainable production practices makes it a preferred supplier for industries seeking robust, long-lasting solutions for elevated temperature applications.

Common inquiries often center on suitability for specific temperature ranges, compatibility with different fluids, and expected lifespan under cyclic thermal loading. Users frequently note the ease of installation, minimal need for post-weld heat treatment, and excellent weldability when handled by qualified technicians. For those considering a transition from standard carbon steel to high-performance alloy piping, ASTM A335 provides a proven upgrade path toward improved energy efficiency, system reliability, and environmental resilience.

Product Categories : High Temperature Steel Pipe > ASTM A335 High Temperature Steel Pipe