Baodely Huaian Metal Technology Co., Ltd.

EN 10216-1 Carbon Steel Pipe,EN Carbon Steel Pipe,High quality EN 10216-1 Steel Pipe

Baodely Huaian Metal Technology Co., Ltd.

EN 10216-1 Carbon Steel Pipe,EN Carbon Steel Pipe,High quality EN 10216-1 Steel Pipe

Model No.: EN 10216-1

Brand: BAODELY

Section Shape: Round

Place Of Origin: China

Application: Fluid Pipe, Boiler Pipe, Hydraulic Pipe, Gas Pipe, Chemical Fertilizer Pipe, Structure Pipe

Production Process: Cold Drawn

Whether Alloy: Non-Alloy

Tolerance: ±10%

Category: Seamless Steel Pipe

Processing Service: Bending, Decoiling, Cutting

Transportation: Ocean,Land

Place of Origin: CHINA

Certificate: ISP9001

Port: SHANGHAI,QINGDAO,LIANYUNGANG

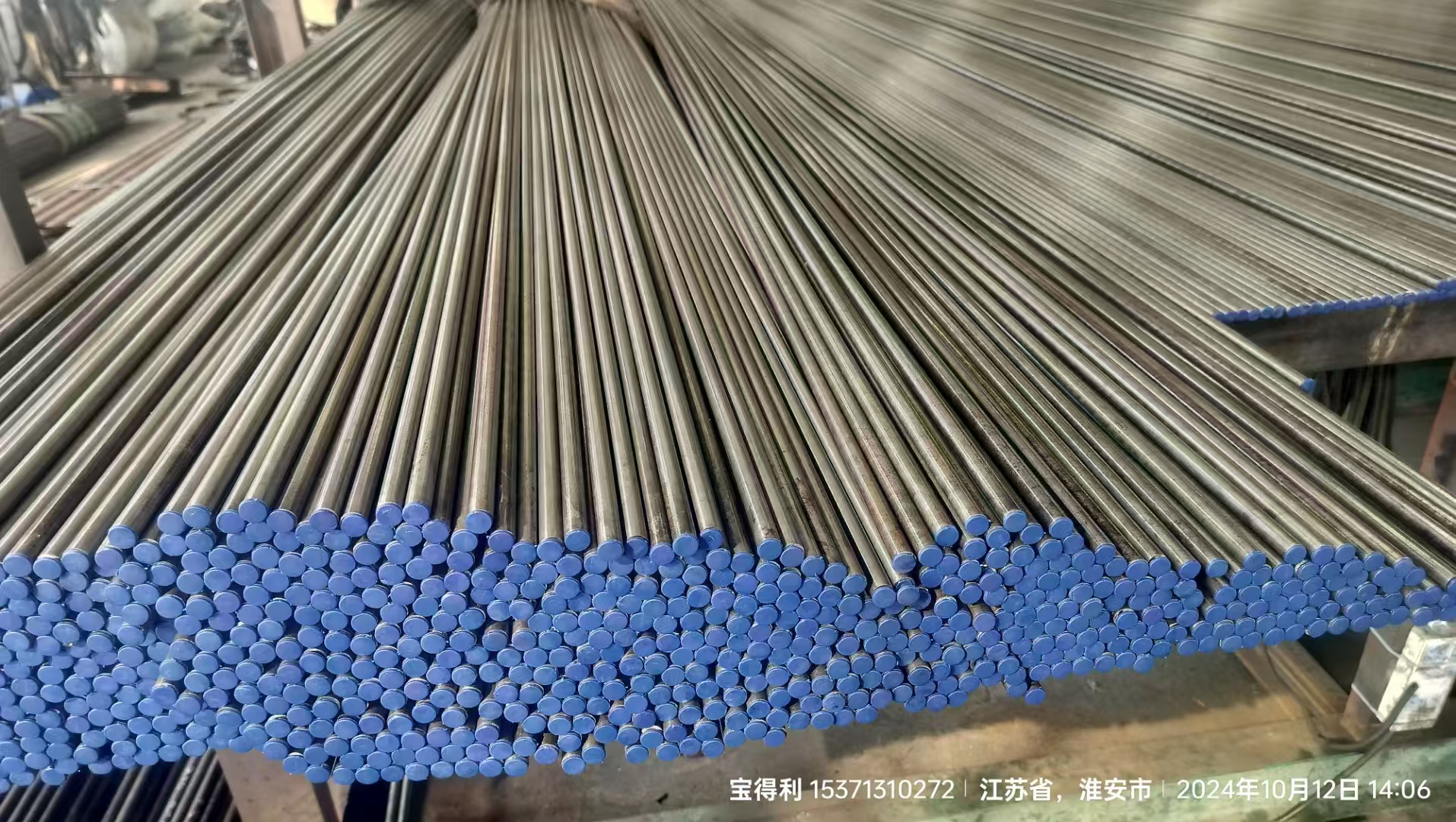

EN 10216-1 Carbon Steel Pipe – Premium Seamless and Welded Solutions for Industrial Applications

Engineered to meet the exacting requirements of the EN 10216-1 standard, this high-grade carbon steel pipe delivers exceptional performance in demanding environments. Manufactured using advanced seamless and welded techniques, it ensures structural integrity, minimal internal resistance, and long-term durability. Ideal for critical infrastructure across multiple sectors, this product combines superior mechanical properties with reliable corrosion resistance, making it a trusted choice for engineers and procurement specialists worldwide.

Key features include outstanding tensile strength, excellent impact toughness at both ambient and elevated temperatures, and a smooth internal finish that reduces frictional losses during fluid or gas transport. Whether used in high-pressure systems or extreme thermal conditions, these pipes maintain consistent performance without compromising safety or efficiency. Their uniform composition and precise dimensional control make them suitable for precision engineering applications where reliability is non-negotiable.

Beyond basic compliance, EN 10216-1 carbon steel pipes are designed for real-world challenges—such as fluctuating pressures, aggressive chemical exposure, and continuous operational cycles. The seamless variant offers enhanced resistance to leakage points, while the welded version provides flexibility in manufacturing scale and cost-effectiveness for large-scale projects. Both variants undergo rigorous quality inspections, including hydrostatic testing and non-destructive evaluation (NDE), ensuring adherence to international metallurgical standards.

These pipes serve as essential components in oil and gas transmission lines, petrochemical processing units, boiler systems, heat exchangers, and industrial heating networks. They support safe conveyance of steam, water, natural gas, and other media under varying environmental conditions—from offshore platforms to onshore refineries. With proven resilience in corrosive atmospheres and high-temperature service, they reduce maintenance frequency and extend asset lifespan significantly.

Industry professionals consistently praise the balance between performance and value offered by this product line. Users highlight its ability to simplify system design due to predictable behavior under stress, reduced need for auxiliary supports, and compatibility with existing piping infrastructure. Many note improved energy efficiency resulting from lower pressure drop, which translates into measurable operational savings over time.

Common questions often revolve around material suitability for cryogenic applications—while primarily intended for ambient to high-temperature use, certain grades can be adapted for low-temperature environments when properly specified. Another frequent inquiry concerns surface treatment options; the standard smooth bore minimizes fouling, but additional coatings may be applied for specific corrosion mitigation needs. Installation best practices emphasize proper alignment, welding procedures, and post-weld heat treatment to preserve mechanical integrity throughout the lifecycle.

Product Categories : Carbon Steel Pipe > EN 10216 Carbon Steel Pipe