Baodely Huaian Metal Technology Co., Ltd.

JIS G3445 Seamless Tube,JIS G3445 Carbon Steel Tube,Carbon Steel Seamless Tube

Baodely Huaian Metal Technology Co., Ltd.

JIS G3445 Seamless Tube,JIS G3445 Carbon Steel Tube,Carbon Steel Seamless Tube

Model No.: JIS G3445

Brand: BAODELY

Standard: Jis

Section Shape: Round

Place Of Origin: China

Application: Fluid Pipe, Boiler Pipe, Hydraulic Pipe, Gas Pipe, Chemical Fertilizer Pipe, Structure Pipe

Production Process: Cold Drawn

Tolerance: ±10%

Category: Seamless Steel Pipe

Processing Service: Bending, Decoiling, Cutting

Transportation: Ocean,Land

Place of Origin: CHINA

Certificate: ISO9001

Port: SHANGHAI,QINGDAO,LIANYUNGANG

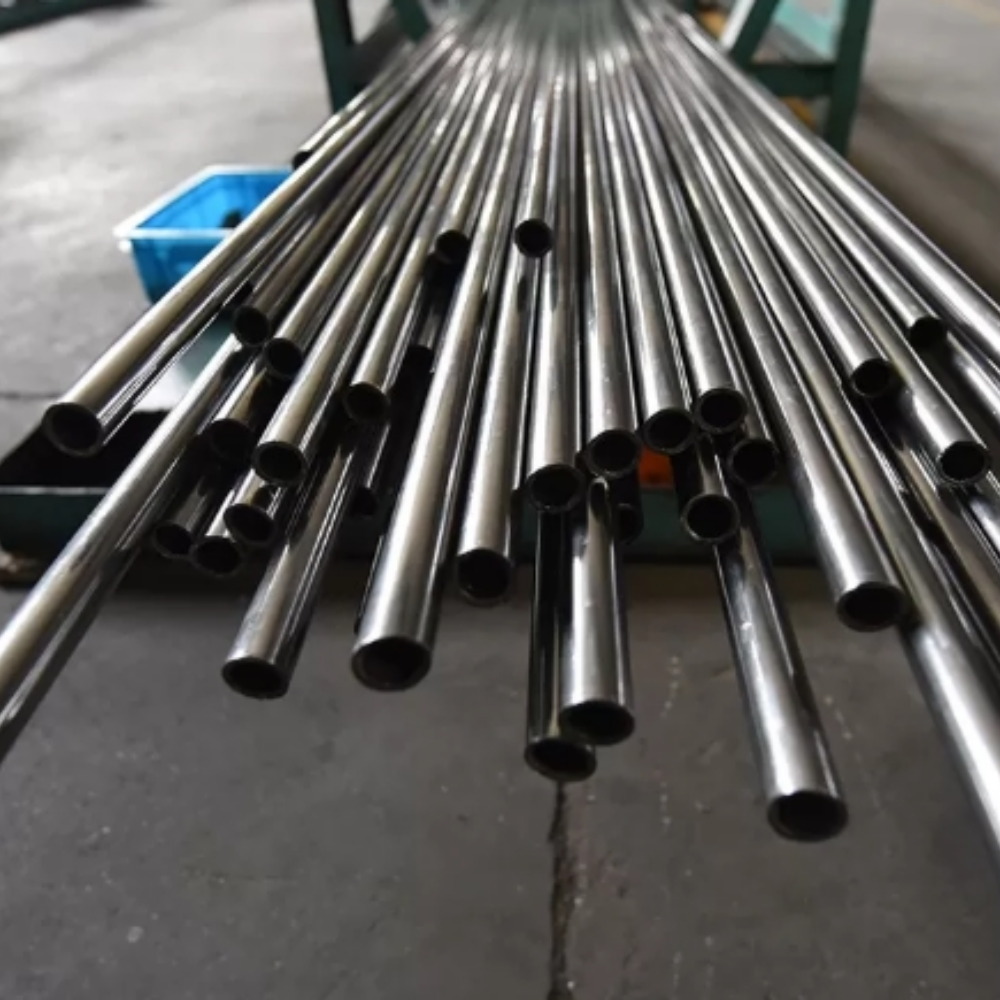

JIS G3445 Carbon Steel Seamless Tube – High-Performance Industrial Pipe for Demanding Applications

Engineered for reliability and performance, the JIS G3445 carbon steel seamless tube is a premium-grade piping solution widely adopted across global industries such as manufacturing, automotive engineering, energy infrastructure, and construction. Manufactured under strict adherence to Japanese Industrial Standards (JIS G3445), this pipe delivers consistent mechanical strength, dimensional precision, and corrosion resistance—making it an ideal choice for both standard and high-stress environments.

Unlike welded alternatives, these seamless tubes are produced using advanced hot rolling and cold working techniques that eliminate weld seams, ensuring uniform wall thickness and eliminating weak points prone to leakage or failure. The precise control over chemical composition—including optimal levels of carbon, manganese, and silicon—enhances ductility, tensile strength, and impact toughness, enabling the pipe to withstand fluctuating pressures, temperature variations, and mechanical stress without compromising integrity.

Key features include a smooth internal and external finish, which facilitates fluid flow efficiency and simplifies installation processes; excellent dimensional accuracy that reduces fitting time during assembly; and inherent resistance to common environmental conditions like moisture, mild acids, and industrial exposure—ideal for use in pipelines, structural supports, hydraulic systems, and heat exchangers. Each unit undergoes rigorous quality assurance checks, including spectrochemical analysis, tensile testing, hydrostatic pressure verification, and non-destructive evaluation (such as ultrasonic or eddy current inspection) to ensure compliance with international standards.

This versatile product serves as a foundational component in machinery fabrication, boiler systems, offshore platforms, scaffolding frameworks, and transportation equipment. Its robustness makes it particularly suitable for applications where safety, longevity, and minimal maintenance are critical factors—ranging from oil and gas transmission lines to HVAC components and heavy-duty vehicle chassis elements.

Users report consistent performance across diverse climates and operational cycles, praising the material’s durability and ease of integration into existing designs. Many engineers highlight how the seamless design minimizes risk of joint failure—an advantage often overlooked in conventional pipes—and contributes significantly to system uptime and cost savings over time.

Common questions revolve around compatibility with various media types, maximum operating temperatures, and suitability for cryogenic environments. While primarily designed for ambient to elevated temperature applications (typically up to 400°C), some variants can be adapted for low-temperature service when properly treated. Always verify specific grade requirements based on your application’s pressure rating, fluid type, and environmental exposure before implementation.

Product Categories : Structural Pipe > JIS G3445 Pipe