Chrome Moly Steel for High Temp Service: Engineered Excellence in Extreme Thermal Environments This premium

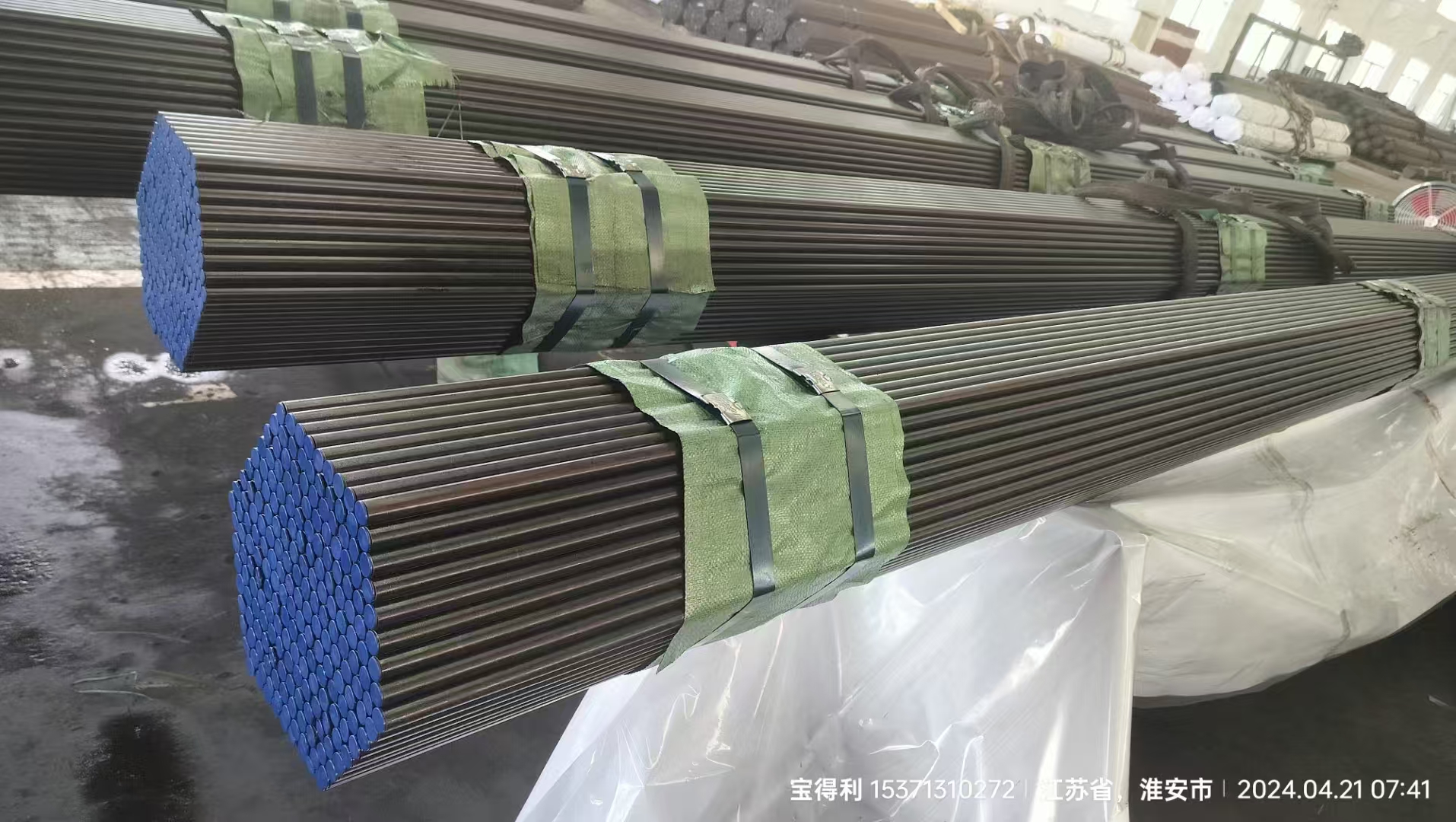

Alloy Steel Pipe is meticulously designed for demanding high-temperature industrial applications where reliability, strength, and corrosion resistance are non-negotiable. As a specialized variant of Alloy Steel Pipe, it excels in environments exceeding 600°C, offering unmatched performance compared to conventional carbon steel or low-temperature alternatives. Its composition—rich in chromium and molybdenum—delivers exceptional oxidation resistance, creep strength, and mechanical stability under prolonged thermal stress. Ideal for critical components in power generation, petrochemical processing, and chemical manufacturing, this seamless high-temperature steel pipe ensures operational continuity, safety, and efficiency across complex systems. Key Features - Superior High-Temperature Resistance: Maintains structural integrity up to 600°C+ without significant loss of tensile or yield strength - Enhanced Corrosion Protection: Chromium content minimizes oxidation in steam, flue gas, and aggressive chemical media - Creep Strength Optimization: Molybdenum stabilizes microstructure, preventing long-term deformation under sustained heat and pressure - Seamless Construction: Eliminates weld weaknesses, enhancing burst resistance and reducing risk of leakage in pressurized systems - Consistent Mechanical Properties: Uniform alloy distribution and controlled rolling ensure predictable behavior during thermal cycling Detailed Description Manufactured using advanced refining techniques, Chrome Moly Steel for High Temp Service undergoes precise smelting, hot rolling, and heat treatment processes that guarantee consistent metallurgical quality. Unlike standard carbon steel pipes—which degrade rapidly above 400°C—this alloy maintains its toughness, impact resistance, and dimensional accuracy even when exposed to fluctuating temperatures and high-pressure conditions. The seamless nature of the pipe, aligned with ASME SA213 standards, eliminates potential failure points found in welded joints, making it ideal for boiler tubes, superheater sections, and reactor piping. Its ability to resist both oxidation and thermal fatigue makes it a preferred choice over generic alloy steels in environments involving cyclic heating and cooling, such as those encountered in modern supercritical power plants or hydrogenation units in refineries. Application Scenarios Commonly used in energy infrastructure like utility boilers, nuclear facilities, and combined cycle gas turbines, this high-temperature pipe also serves vital roles in chemical reactors, distillation columns, and high-pressure process lines. It supports safe operation in extreme conditions where failure could lead to catastrophic downtime or environmental hazards. Compared to

Low Temperature Steel Pipe, which prioritizes fracture toughness at sub-zero temperatures, Chrome Moly Steel focuses exclusively on thermal resilience—making it an indispensable material for any system requiring sustained performance at elevated temperatures. Whether in large-scale industrial boilers or high-temperature process equipment, it provides superior durability and reduces maintenance frequency due to its stable microstructure and minimal degradation over time. User Feedback Operators in global energy and chemical sectors consistently report improved system uptime and reduced inspection intervals when deploying Chrome Moly Steel for High Temp Service. Many cite its ability to withstand harsh operating cycles without signs of embrittlement or surface degradation—a common issue with less advanced materials. Industry professionals appreciate how its performance aligns with stringent international codes such as ASME B31.1 and ISO 31000, reinforcing compliance while optimizing asset life. Frequently Asked Questions What distinguishes Chrome Moly Steel from regular carbon steel in high-temp settings? While carbon steel performs well at ambient temperatures, it suffers rapid strength loss and oxidation above 400°C. Chrome Moly Steel’s alloying elements preserve mechanical properties and resist corrosion even in continuous exposure to extreme heat. How does it compare to

Precision Steel Pipe? Precision Steel Pipe emphasizes tight dimensional tolerances and smooth finishes; Chrome Moly Steel prioritizes uniform alloy content and internal grain structure stability for high-temperature service. Both may be used together in integrated systems but serve different functional purposes. Is it suitable for use in supercritical boilers? Yes—its proven performance in ultra-supercritical and supercritical power station boilers confirms its suitability for next-generation thermal power systems where efficiency and safety must coexist.

Product Categories : Boiler Pipe > ASME SA213 Boiler Pipe