ASME SA213 T11 (12Cr1Mo)

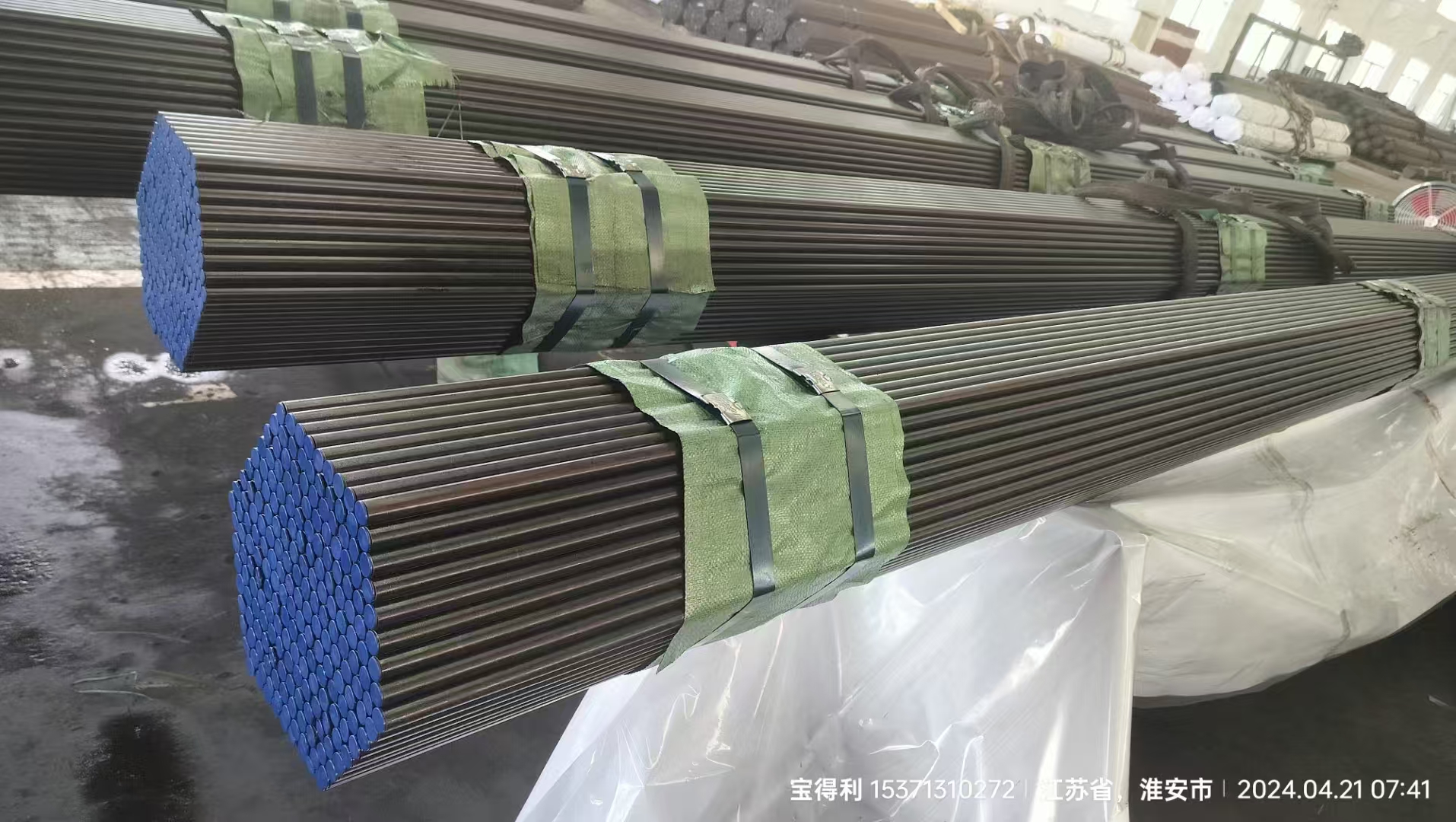

Seamless Steel Tube – High-Temperature Alloy Boiler Tube for Industrial Power Systems Engineered for extreme thermal environments, the ASME SA213 T11 seamless steel tube—also recognized as 12Cr1Mo—is a premium chromium-molybdenum alloy solution designed to deliver consistent performance under high pressure and elevated temperatures. This material serves as a cornerstone in critical infrastructure across power generation, petrochemical processing, and industrial heating systems worldwide. Its unique metallurgical composition ensures superior creep resistance, oxidation stability, and mechanical integrity, making it an ideal choice for components like superheaters, economizers, and heat exchangers where long-term reliability is non-negotiable. Key Features: - Chromium-enhanced corrosion resistance at high operating temperatures - Molybdenum-based microstructure optimization for improved thermal fatigue strength - Seamless construction eliminates weld defects, enhancing structural continuity - Normalized or normalized-tempered heat treatment for uniform grain refinement - Compliant with ASME SA213/SA213M,

Astm A213/A213M, and ISO 9328-1 standards - Available in straight lengths (6–12 meters) or coiled form for flexible installation - Surface treated to meet clean, degreased specifications suitable for hygienic industrial applications In-depth Description: This alloy steel tube belongs to the ferritic class of materials, combining carbon, chromium (approx. 1%), and molybdenum (approx. 0.25%) to achieve exceptional performance in environments exceeding 550°C. The addition of chromium forms a protective oxide layer that resists scaling and oxidation during prolonged exposure to steam or combustion gases. Meanwhile, molybdenum enhances creep rupture strength—a crucial factor in boiler tubes subjected to continuous stress over thousands of hours. Unlike austenitic stainless steels, which offer higher corrosion resistance but lower thermal conductivity, T11 provides a balanced mix of cost-efficiency, durability, and thermal efficiency, especially in medium-pressure steam systems found in utility-scale boilers and HRSGs (Heat Recovery Steam Generators). The manufacturing process includes cold drawing followed by precise heat treatment, ensuring dimensional accuracy, surface finish quality, and internal homogeneity essential for safe operation in pressurized vessels. Ideal Applications: Commonly specified in fossil fuel power plants, refineries, and chemical processing units, this seamless alloy tube excels in environments involving saturated or superheated steam, hot oil circulation, and gas transfer. It supports efficient heat transfer in boiler tubes, reheater sections, and piping networks where thermal cycling and mechanical loading are frequent. While not recommended for highly corrosive media such as acidic condensates or wet CO₂ atmospheres, its performance in dry, high-temperature conditions makes it a preferred alternative to more expensive nickel-based alloys in many global markets. User Feedback: Operators in Europe, North America, and Southeast Asia have reported extended service life when properly maintained, often exceeding 15 years in stationary boiler installations. Users appreciate the predictable behavior under cyclic thermal loads and note minimal distortion even after repeated start-stop cycles. Maintenance teams highlight ease of inspection due to consistent surface quality and compatibility with standard NDT methods like ultrasonic testing and dye penetrant analysis. Frequently Asked Questions: What distinguishes ASME SA213 T11 from other boiler-grade tubes? It offers a proven balance between cost-effectiveness and performance in high-temperature applications, particularly where austenitic stainless steels would be unnecessarily costly. Is it suitable for use in nuclear or marine environments? No—it is primarily intended for conventional power generation and industrial heating systems; specialized alloys are required for nuclear-grade or saltwater exposure scenarios. How does it perform compared to carbon steel at elevated temperatures? Unlike carbon steel, which begins to lose strength above 400°C, T11 maintains structural integrity up to approximately 570°C, significantly reducing failure risk in demanding thermal applications. Can it be welded using standard procedures? Yes—with appropriate preheat and post-weld heat treatment per ASME BPVC Section IX guidelines—to preserve the alloy’s mechanical properties and avoid embrittlement in the heat-affected zone. For industries seeking reliable, long-lasting tubing solutions for steam systems, ASME SA213 T11 stands out as a globally trusted material that combines engineering excellence with economic viability.

Product Categories : Boiler Pipe > ASME SA213 Boiler Pipe