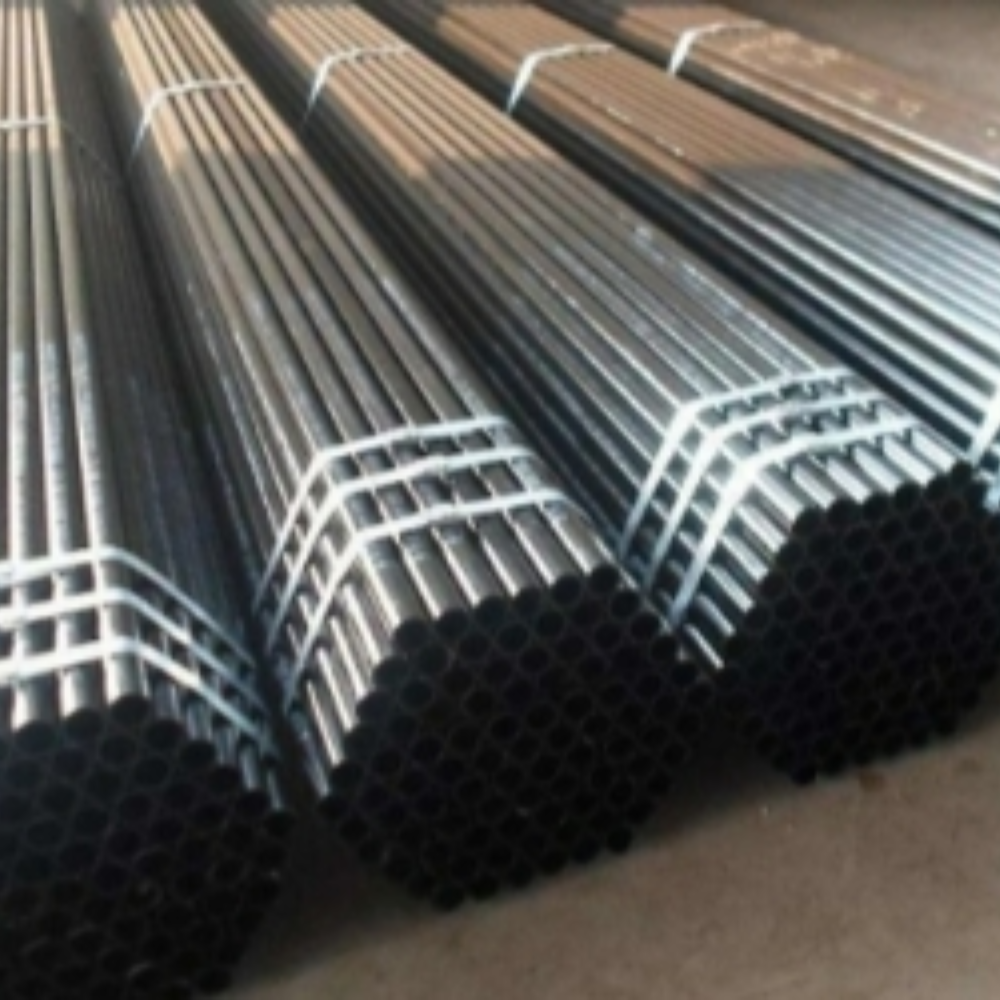

JIS G 3454

Pressure Steel Pipe – High-Performance Solution for Industrial Fluid Systems This premium-grade pressure steel pipe, compliant with the JIS G 3454 standard, is engineered for demanding applications across global industries such as oil and gas, petrochemicals, power generation, and infrastructure. Designed to withstand high internal pressures while maintaining structural integrity, it serves as a reliable backbone in critical fluid transport systems worldwide. Engineered for exceptional mechanical performance, this

Carbon Steel Pipe features a precisely controlled chemical composition—optimized levels of carbon, manganese, silicon, and trace alloying elements—to deliver superior tensile strength, impact resistance, and ductility. The manufacturing process involves advanced hot rolling, seamless forming, and precision heat treatment, ensuring consistent wall thickness, minimal dimensional deviation, and uniform microstructure. These factors collectively reduce stress concentration points and enhance fatigue life under cyclic loading conditions. What sets this product apart are its stringent quality control measures: every pipe undergoes hydrostatic pressure testing, ultrasonic non-destructive evaluation (NDE), and mechanical property verification—including yield strength, ultimate tensile strength, and elongation tests—to guarantee compliance with international standards. The smooth, clean inner and outer surfaces not only minimize flow resistance but also provide enhanced corrosion resistance against various media like water, steam, natural gas, and chemical solutions. Ideal for use in pipelines requiring long-term reliability under variable temperature and pressure conditions, these pipes are commonly found in refinery units, offshore platforms, boiler feed systems, and industrial process lines. Their robust design supports both static and dynamic load scenarios, making them suitable for both above-ground and buried installations across diverse climates—from arid desert environments to coastal salt-laden atmospheres. Users from Europe, North America, and Asia have consistently praised the material consistency, weldability, and ease of installation. Many report reduced maintenance costs and fewer leaks compared to lower-grade alternatives, especially when integrated into high-pressure steam or compressed air networks. Industry professionals often highlight how the pipe’s predictable behavior under extreme conditions improves system uptime and operational safety. Common questions include whether the pipe can handle elevated temperatures or resist corrosion in aggressive media—yes, due to its metallurgical stability and surface finish. Another frequent inquiry concerns compatibility with welding procedures; the pipe performs well with common joining methods such as TIG, MIG, and submerged arc welding when proper preheat and post-weld heat treatment are applied. Baodely Huaian Metal Technology Co., Ltd. specializes in producing precision seamless steel tubes tailored to global engineering demands. With a focus on quality assurance, competitive pricing, and technical support, they offer a range of products including low-temperature carbon steel pipe, alloy steel tubing, boiler-grade pipes, and custom-engineered solutions—all manufactured under strict adherence to international specifications beyond just JIS G 3454. Whether you're specifying materials for a new pipeline project or replacing aging components in an existing facility, this JIS G 3454-compliant pressure steel pipe offers unmatched value through durability, safety, and proven performance.

Product Categories : Pressure Steel Pipe > JIS G3454 Pipe