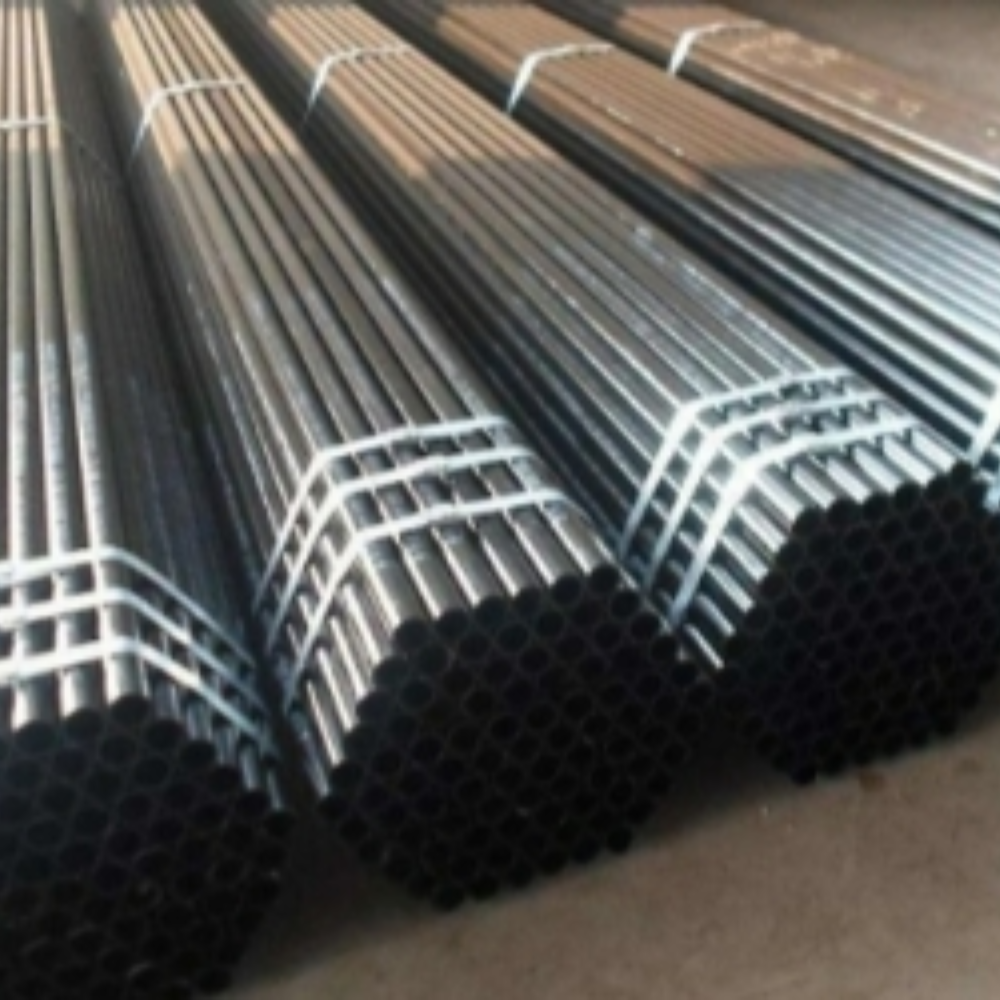

JIS G 3454 Pressure Pipe – High-Performance Steel Solution for Industrial Applications This premium pressure pipe, compliant with the stringent JIS G 3454 standard, is engineered for demanding industrial environments where strength, durability, and safety are paramount. Designed for seamless or welded construction using high-grade carbon steel, it delivers exceptional mechanical properties under extreme conditions. The precise alloy composition—carefully balanced with carbon, manganese, silicon, and trace elements—ensures superior tensile strength, impact resistance, and ductility. These attributes make it an ideal choice for pipelines transporting fluids and gases in high-pressure systems across global industries. Key Features - Compliant with JIS G 3454 specifications for consistent quality assurance - Seamless or welded manufacturing for uniform wall thickness and minimal stress concentration - Enhanced toughness and corrosion resistance suitable for aggressive chemical and thermal environments - Rigorous non-destructive testing (NDT) and hydrostatic pressure verification per international standards - Manufactured from certified raw materials to ensure reliability and long-term performance In-depth Description The JIS G 3454 pressure pipe is not just a conduit—it’s a critical component of infrastructure integrity. Its microstructure, developed through controlled rolling and heat treatment processes, provides optimal grain refinement that supports fatigue resistance and crack propagation control. Unlike conventional pipes that may develop weak points due to inconsistent wall thickness or weld imperfections, this product undergoes advanced forming techniques such as cold pilgering or hot extrusion, ensuring dimensional accuracy and structural homogeneity. Each batch is subjected to comprehensive inspections including ultrasonic testing, radiographic examination, and hardness profiling to meet global engineering expectations. Whether used in offshore platforms, refineries, power plants, or petrochemical facilities, these pipes offer peace of mind through predictable behavior under cyclic loading and elevated temperatures. Applications Across Industries Commonly deployed in oil & gas transmission lines, chemical processing units, steam distribution networks, and district heating systems, this pipe type excels in applications requiring reliable containment of pressurized media. It serves as a backbone for industrial fluid transport systems in regions ranging from North America to Europe and Southeast Asia, particularly where compliance with international codes like ASME B36.10M, EN 10216-2, or ISO 3183 is mandatory. Due to its inherent resistance to atmospheric and aqueous corrosion, it also performs well in marine environments or humid climates where traditional steels might degrade prematurely. Customer Testimonials Users have consistently praised the pipe’s robustness during installation and operation. One engineer from a European energy firm noted, “We’ve seen zero failures over five years of continuous operation at 150 bar pressure.” Another client in the Middle East highlighted the ease of welding without compromising joint integrity—a common challenge with lower-grade materials. Feedback emphasizes consistency in performance, even in fluctuating temperature ranges from -40°C to +400°C. Frequently Asked Questions What makes JIS G 3454 different from other pressure pipe standards? It specifies tighter tolerances on chemical composition, mechanical properties, and surface finish, making it more suitable for critical service conditions compared to general-purpose ASTM A106 or API 5L grades. Can it handle corrosive media? Yes, while not inherently stainless, its surface treatment and controlled alloy content provide adequate protection against mild acids, alkalis, and saline solutions when properly maintained. Is it suitable for cryogenic use? Certain grades within the JIS G 3454 classification are certified for low-temperature service down to -40°C, making them appropriate for LNG transportation and refrigeration systems. How does it perform under dynamic loads? Thanks to its fine-grained structure and uniform manufacturing, it exhibits excellent fatigue life, reducing the risk of failure in vibrating or pulsating flow systems. Baodely Huaian Metal Technology Co., Ltd. continues to lead in

Precision Steel Pipe production, offering a full range of products including Carbon Steel Pipes, Low-Temperature Alloy Pipes, Boiler Tubes, and Precision Seamless Steel Pipes—all backed by rigorous quality management systems and global certifications.

Product Categories : Pressure Steel Pipe > JIS G3454 Pipe